CASE STUDY-1

STAYING IN THE SAFE ZONE WITH VIBRATION AND SOUND ANALYSIS, MONITORING AND CONTROLLING

(Impact of Vibrations and Sounds in Plant and Machinery)

About Company:

A soft drink manufacturing company employs over 5,000 people in sites, warehouses and offices all over the country. The company Is responsible for manufacturing and distributing a wide range of different drinks products to customers throughout the country and some neighbor countries also. The following measurements were taken at the Mysore road facility in Bangalore.

The regional service station is the largest warehouse in the Manufacturing network. It occupies 2, 50,000sq.ft holds over 100 different products.

Problem:

The company has the following concerns:

The maintenance manager has the following concerns:

- The excess vibration of some machines.

- Employee’s health issues associated with the vibration and sound.

- Level of vibration in the plant will affect the quality of the product.

- Overall Vibration level should be according to the standards.

Control of vibration at work regulations (2005)

Table of exposure limits according to Government Regulations

| Daily exposure Average | Daily exposure limit | |

| Hand arm vibration | 2.5m/s² | 5 m/s² |

| Whole body vibration | 0.5m/s² | 1.15 m/s² |

Control of noise at work regulations (2005)

| Average level of exposure dB (A) | Peak level of exposure dB(C) | |

| Lower exposure limit | 80 | 135 |

| Upper exposure limit | 85 | 137 |

| Exposure limit value | 87 | 140 |

.The regulations are designed to prevent the health risks associated with employees exposure to vibration and noise in the workplace, like back pain & hearing loss respectively.

Solution:

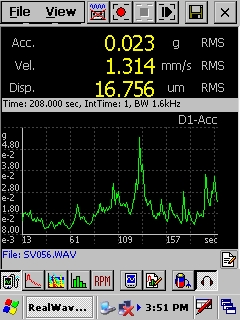

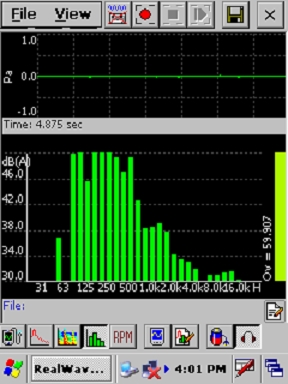

The company wanted to measure the vibration and noise frequencies on site using advanced portable devices like Digital vibration Analyzer and Sound level meter and Analyzer for frequency measurement and analysis to know the levels at the site boundary.

The obtained data was further analyzed in vibration analysis PC software and compared with the limit values defined in the regulations.

The values are as follows:

Vibration:

Hand arm vibration 5.2m/s² >5m/s² (daily exposure limit) Whole body vibration 1.28m/s²>1.15m/s²(daily exposure limit)

Sound:

| Lower exposure Limit | 90 dB (More than Average level of exposure) |

| Upper exposure Limit | 97 dB (More than Average level of exposure) |

| Exposure Limit value | 92 dB (More than Average level of exposure) |

The Quality manager analyzed the data and suggested the staff to implement few changes in the machinery according to the Analysis

Following the vibration and noise measurements, The Company has issued new hearing protecting systems and also replaced some equipment and accessories.

A few weeks later, the company repeated the same measurement with the Vibration and Sound meter. The results showed the reduced and balanced level of vibration and sound on site after changing the new equipment and implementing protection.

| Hand arm vibration | 3.5m/s² <5m/s² (daily exposure limit) |

| Whole body vibration | 0.95m/s²<1.15m/s²(daily exposure limit) |

| Lower exposure Limit | 71 dB (Near to Average level of exposure) |

| Upper exposure Limit | 74 dB (Near to Average level of exposure) |

| Exposure Limit value | 76 dB (Near to Average level of exposure) |

The company was pleased with the results of the devices

Outcome/Benefits:

| Financial loss/benefits |

| Daily Production = 100 tons |

| Price/ton= 1 million ₹(10Lakhs) i.e. 100 tons= 100 million₹ (10 crore) |

| Resource loss/benefits |

| Machinery replacement cost =5-10 lakh ₹ * Maintenance persons wages = 1 lakh₹ * Cost of time delay and order losses =2-5 lakh₹ * All these losses will be avoided if the vibration and sound levels are in control according to the standards .Regular monitoring is necessary to avoid this. |

In the above table *=Approximate

From the above table, we can predict how much loss the company would have faced if the sounds and vibrations are not monitored at regular basis; it will cost both the financial and resource loss to the company.

Are you facing the same problem? Want to check the vibration and sound level in your facilities. No worries… we are here to help you. We have the best in the industry advanced vibration and noise measuring devices.

For more details visit: www.svibtech.net

Contact us : Sales@svibtech.net / 7259253724

Contact us : Sales@svibtech.net / 7259253724