Paper Mill machinery breakdown analysis and fault detection using Vibration Analyzer

-A case study from a paper mill.

This study describes a vibration monitoring program in operation at a paper mill. The case described here of how faults have been detected on paper machines using vibration measurement.

Faults have been detected long before they could become critical, enabling repair to be scheduled for planned production shutdowns.

About Papermill

This paper mill is a part of India’s leading producer of newsprint and papers, and one of the largest industrial companies in the country.

This paper mill operates three paper machines and produces newspapers and magazines, which is reputed to be some of the best.

Their paper machine produces around 100 tons of paper per day. At a loss of just one day’s production would be in some millions. And the cost of maintenance and replacement, loss of time becomes huge.

| Daily Production =100 tons of paper |

| Market price of paper 32,000* ₹./Ton => 32,00,000* ₹/100 tons. |

| 1 shut down cost= 32,00,000* ₹+Cost of maintenance +Cost of replacement +Loss of order |

| Average cost of Vibration Monitoring devices= 2, 50,000 INR* + maintenance person salary (50,000*) = 3, 00,000 *> Which is 10 times less than the cost of shutdown |

Table:1

- In the above table *=Approximate

Problems/ issues: The following problems were found by the mills’ maintenance department.

- Unexpected machine failures.

- Huge breakdown cost.

- Unusual vibrations and sounds in machinery

- The production of paper is a highly competitive industry, one downtime or breakdown will cost a lot. To avoid this problem and ensure continuous and profitable production, Mills maintenance must bring in new equipment to tackle these problems.

- The use of vibration monitoring devices to analyze the condition of the machinery in the plant is very vital.

- In many cases, the consequences of not having detected the fault would have been almost stopped in certain productions. It results in the lost production and expensive maintenance.

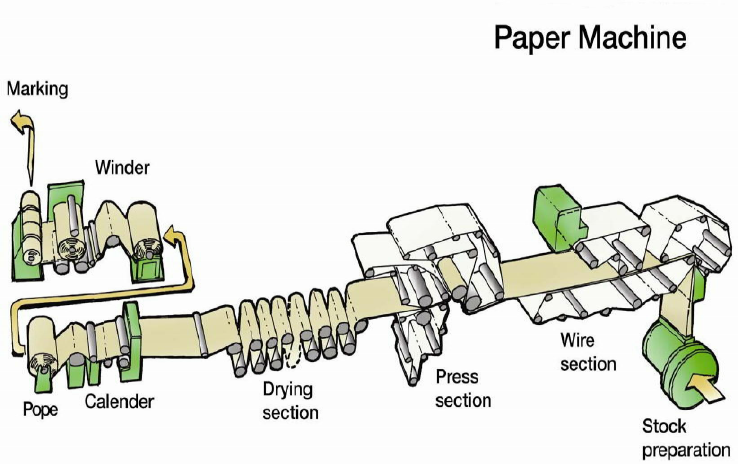

- Below figure shows the complex arrangement of a paper machine. The paper machine is the most critical sections in the round the clock paper production process.

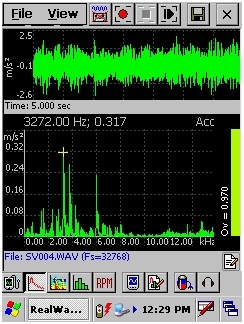

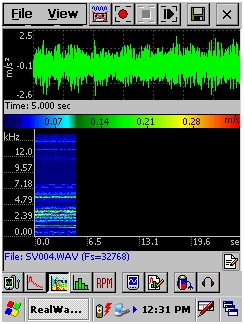

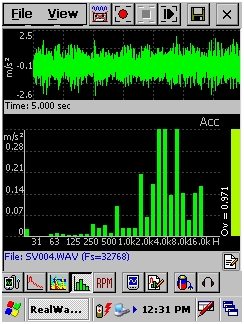

Vibration Analysis:

Below mentioned are standard vibration levels for class II machines. According to ISO-2372

| Standard Vibration Level | Machine Condition |

| Up to 2.8 mm/sec. | Normal |

| 2.8 to 7.1 mm/sec. | Marginal |

| Above 7.1 mm/sec. | Critical |

Table:2

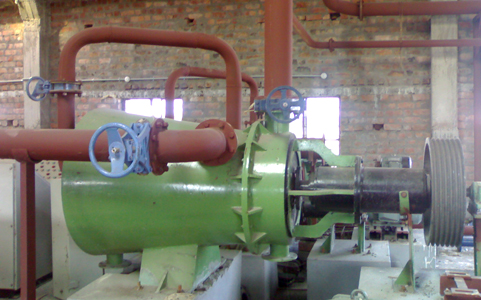

Object: Motor 1:

| Equipment Name | MTR/001 |

| Equipment No | Motor 1 |

| Speed | 2000 |

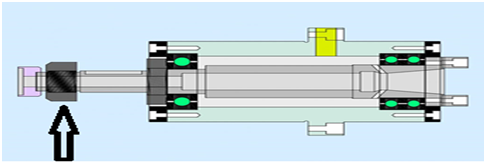

In the above figure, the arrow represents, where the sensors are connected to measure vibration

Observation:

| Horizontal | Vertical | Axial | |

| Acceleration (g) | 0.174 | 0.259 | 0.079 |

| Velocity (mm/s) | 0.121 | 0.119 | 0.086 |

| Displacement (um) | 5.325 | 0.138 | 10.321 |

| Condition: | Marginal |

- The analysis shows that the Condition of this motor1 (MTR/001) is Marginal according to the vibration standards of class II machines. According to ISO ISO-2372 (Refer:Table 2)

- Similarly, all the machines and motors were analyzed using vibration analyzer; the machines which were found faulty were replaced.

- Since the installation of the vibration monitoring equipment at the paper mill, there have been no unexpected breakdowns on monitored machines.

- All the problems have been detected earlier to enable repair to be scheduled for a planned shutdown.

Are you facing the same problem? Want to check the vibration and sound level in your facilities. No worries… we are here to help you. We have the best in the industry advanced vibration and noise measuring devices.

For more details visit: www.svibtech.net

Contact us : sales@svibtech.net / +91 7259253724

Contact us : sales@svibtech.net / +91 7259253724