Guide to choose the best Vibration and Sound measuring device.

Confused? Choosing the best measurement device?

Here is the Guide to choose the best Vibration and sound measuring device.

In this blog, we will discuss:

- Why use vibration measuring devices.

- How the vibration measurement devices work.

- Tips/guide in choosing the best device

Why use Vibration measuring devices?

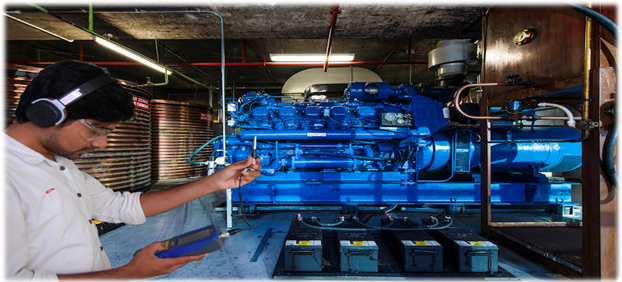

- Vibration is measured to detect machinery failures before it occurs. It avoids and helps from unplanned machinery failures and shutdown.

- It allows machinery to be replaced or repaired before the unplanned shutdown

- All the machinery have a usual vibration at the speed it is operated and runs, but it changes with time and usage, and if the operating conditions change. Vibration measurement and analysis can help deduct the fault conditions.

- When a change is observed in vibration than the usual, the vibration data is collected and analyzed, which allows us to detect the fault conditions such as bearing faults, misalignment, looseness, and

- Investing in vibration measuring devices will be most effective for the companies which have rotating machinery.

- A good quality vibration analyzer will help cut down the breakdown costs of machinery which is higher and expensive

How Do Vibration measuring devices work?

- Vibration measuring devices basically vibration meter or analyzer is an electronic device which is able to process signals of vibration.

- The sensor is connected to the vibrating machine and the device, the vibration device process the signals received from the vibration and display the vibration parameters.

- Vibration is generally expressed by Time domain parameters (Displacement, Velocity, and Acceleration) or Frequency domain parameters (Spectrum, Phase…etc).

Frequency: Frequency means the number times, the vibrating object generates a repetitive motion in 1 second. Unit=Hz.

Displacement: Displacement means the distance between the peaks of vibration. Unit=µm, mm

Velocity: Velocity means the changing rate of displacement to time. Unit=mm/s, cm/s

Acceleration: Acceleration means the changing rate of velocity (V) to time. Unit=m/s²,g

How to choose the correct device?

Choosing vibration measuring devices is also a critical part, you should be able to differentiate between the variety of devices and their usage. Before buying you have to consider the following

- Usage/applicability of the device

- Types of measurements, based on the machinery and industry

- You should always consult a vibration monitoring experts before buying a device.

We here at SVIB are always ready and committed to helping the customers in choosing the best vibration measuring devices according to their application and use.

Types of Vibration measuring devices:

Usually, Vibration measuring devices come in different types and models, based on usage and application you can choose one.

They comprise a transducer, data acquisition and an attached display screen for further processing you can collect the data and see in pc software.

- Handheld Vibration Meter ( PM 101)

- Handheld Sound Level Meter (PM 102)

- Handheld Vibration Analyzer (PA 201)

- Portable Low-frequency Vibrometer or Seismic meter (for Blast-induced and environment vibration and sound analysis) SV1

Vibration Level Meter: (PM 101)

A vibration meter is a small handheld device with a display and memory to record and store measurement values; it comes with a magnetic sensor

True RMS, Peak, Pk-Pk of Acceleration, Velocity and displacement can be measured

It is suitable for checking the level of vibration in fans, blowers, turbines, generators, rotary or balanced opposed compressors, pumps, motors, alternators, engines, gearboxes, bearing etc.

Easy to use: Just connect the sensor, attach a magnetic base or the probe, contact it to the point where the vibration is to be measured, choose appropriate scale and the units for the digital vibration readings

It is suitable if you are just looking for vibration parameters.

Vibration Analyzer:(PA 201)

Vibration Analyzer is the advanced level device, with many options and measurement modes and it is a multi-channel device. It has a Touchscreen display to see the graphs

It has the following options:

- Vibration Level Meter(VLM)

- TTL-based RPM and FFT-based RPM Meter(RPM)

- IRD 810 Filter Built-in / ERP Support(Required Customizing)

- Temperature Display

- FFT Analysis(FFT)

- FFT-based Octave Analysis(OCT)

- Digital Filter-based Octave Analysis(DOCT)

- Spectrogram Analysis(SPEC)

- Sound Level Meter(SLM)

- Ship Vibration Level Meter(SVLM)

It is suitable for checking vibration/sound level as well as the location(Spectrum analysis),RPM, Temperature, Octave analysis and spectrogram of fault in fans, blowers, turbines, generators, rotary or balanced opposed compressors, pumps, motors, alternators, engines, gearboxes, bearing etc.

Desktop Software

- Time Trace Data Display

- Octave Data Graph Display

- FFT Data Graph Display

- Text Data Display

- PC-based Replay (Wave File)

- Peak Value Auto Search at the Selected Area

- Data Administration & Report

Low-frequency Vibrometer or Seismic meter (for Blast-induced and environment vibration and sound analysis) (SV1):

This is a portable and rugged device made for measuring very low-frequency ground vibrations with a large TFT (Touchscreen) display to see vibration trends

This is mostly useful in Seismic Monitoring, Mining Monitoring, Ground Vibration Monitoring, Blast Monitoring, Pile Driving, Construction Field, Bridge Monitoring, Power Plant Monitoring, and Building Vibration Monitoring

The recorded data can be replayed and graphs can be seen on the device screen only, For further processing, the recorded files can be converted into graphs and analyzed using BLS and EVS Pc Softwares provided by the company.

This device has three recording options:

- Manual Mode (Manually start and stop the recording)

- Single Trigger Mode ( Set a level of vibration-when to record)

- Continuous Mode (Set a level at which the vibration is recorded continuously whenever the level reaches the trigger point)

This device is most helpful in field calculation during blasting, The device can be installed with the continuous trigger recording, And it keeps on recording the blast vibration and sound by itself until manually stopped.

Conclusion

Vibration measurement and analysis is one of the best methods to know the actual condition of the machinery, it analyzes and gives the report to schedule repairs.

By understanding the types of devices available from the above details, now we can able to choose the best device according to our usage.

- If you want to just see the vibration parameters of a machinery you can choose PM 101 (Handheld vibration meter), Similarly to see the Sound parameters you can choose PM 102 (Sound Level Meter)

- If you want to see the origin or location of vibration, then you can choose PA 201 (Handheld Vibration Analyzer) which has Spectrum analysis, RPM, Temperature, Octave analysis and spectrogram to detect the faults.

- If you want to measure the low-frequency vibrations like blast and ground vibration you can choose SV1 (Blast-induced vibration and sound analyzer).

Are you facing any difficulties in choosing the best device? Or you have any doubts related to vibration and sound measurement, Contact us: You are just one phone call away in solving all your machinery problems.