Rotatory Motion

Rotational motion is everywhere. When you push a door, it rotates. When you pedal a bike, the wheel rotates. When you start an engine, many parts rotate. Electrons rotate in an atom. Galaxies rotate in the universe. The earth translates and rotates. Ice skaters translate and rotate. Oxygen molecules translate, rotate, and oscillate.

We all know generally what it means if an object is rotating. Instead of translating, moving in a straight line, the object moves about an axis in a circle. Frequently, this axis is part of the object that is rotating. Consider a bicycle wheel. When the wheel is spinning, the axis of rotation is simply a line going through the center of the wheel and perpendicular to the plane of the wheel.

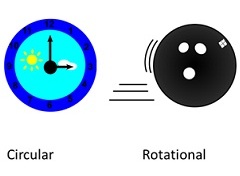

Difference between circular motion and rotational motion:

In the rotation, the body’s center of mass does not undergo any translation motion. In other words, the center of mass will remain at one place

In a circular motion, the body’s center of mass goes around a fixed center maintaining a constant distance from it. Which means the center of mass is actually going through a translation motion.

Now to make matters clear.

Look at a rotating fan. The entire fan is not going anywhere and just spinning around its axle. That’s rotation motion for the entire fan.

Now, look at the blades of the fan. The centers of the blade are going around the axle but actually making a translation motion. Hence the blades are in circular motion.

I hope you got the difference. If the center of mass is not moving then rotation and if moving in a circle then circular.

Also Read : what is vibration? to understand Rotations better

The significance of Rotational motion:

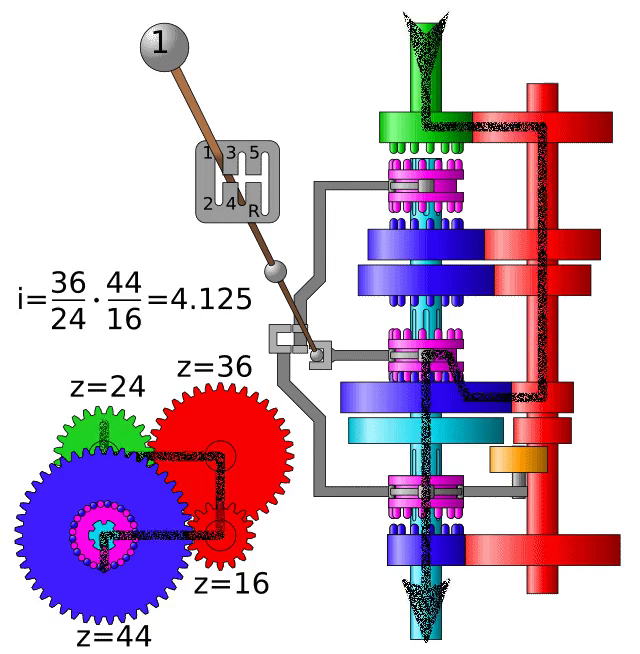

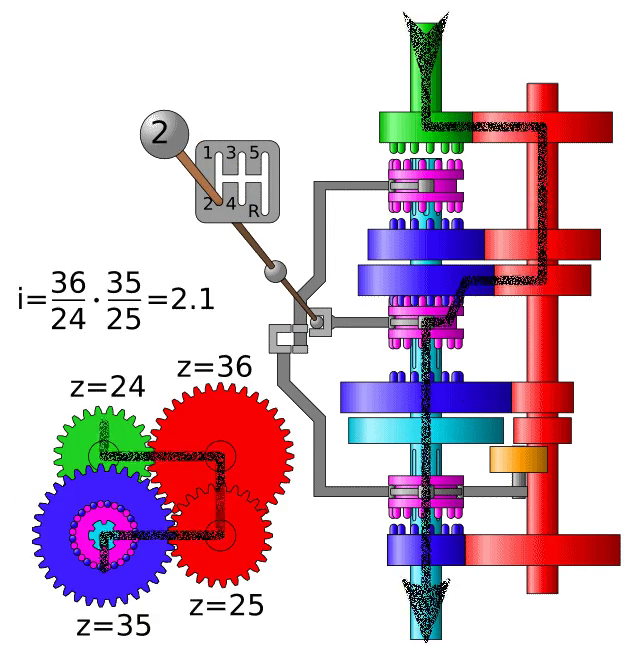

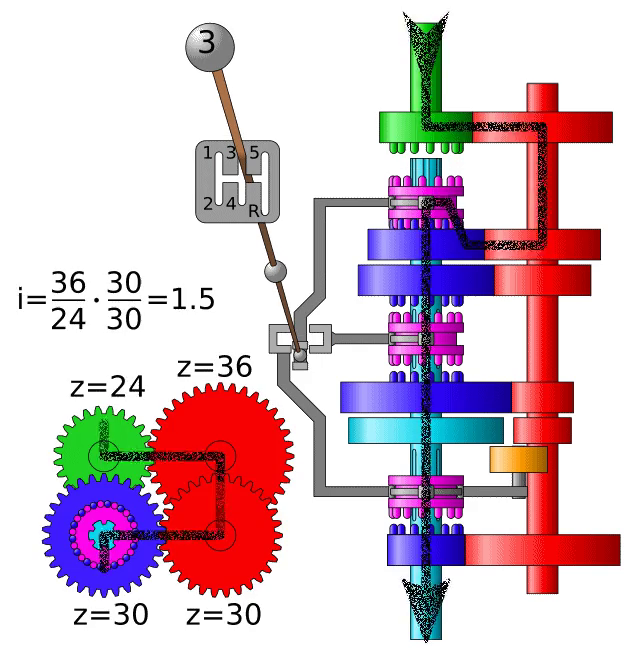

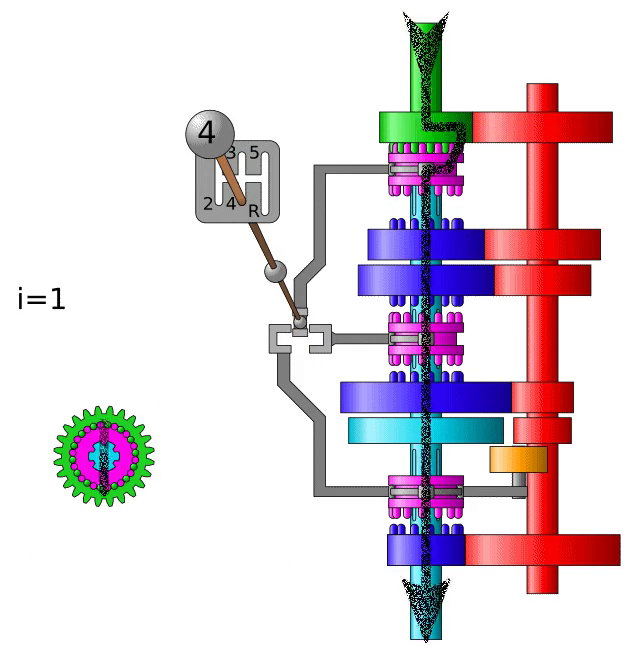

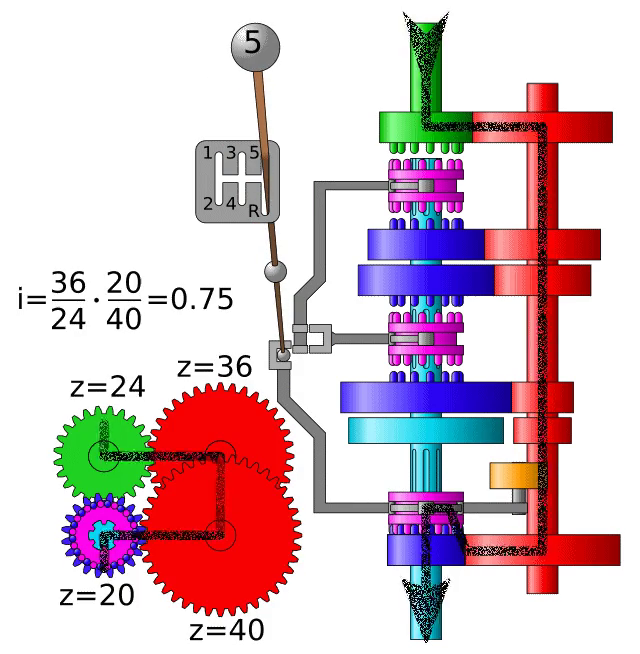

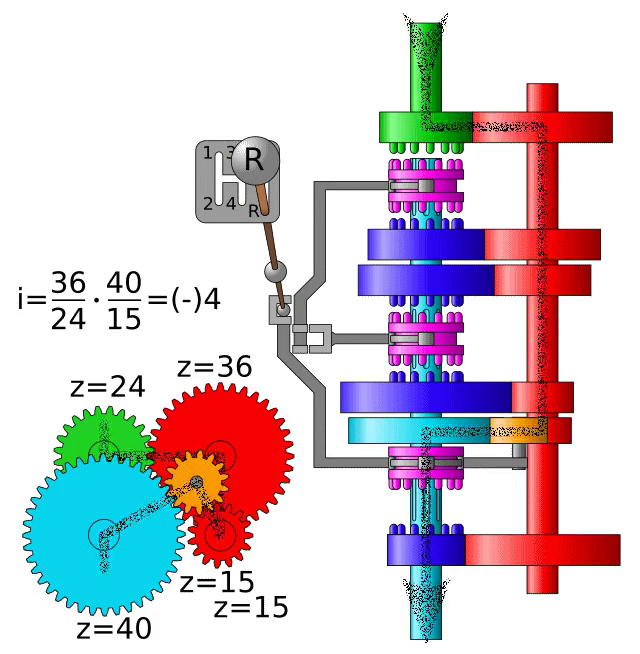

Rotations in a Gear Box: In different Gears

A car engine is a very interesting device, it has an efficiency associated with it (energy in = fuel, energy out = vehicle speed).

This efficiency is not a constant number, “” It changes with RPM “” << this is important. Mostly, engines will have a low efficiency at both low and very high RPMs, and they have a peak efficiency in the middle.

One of the reasons people came up with a transmission is to run the engine at peak efficiency most of the time. When you are in a particular gear and you accelerate, the RPMs would increase and the engine may not be running at peak efficiency anymore.

So, you shift up (choose a lower ratio) to run the engine at lower RPMs while keeping the vehicle speed the same. Shifting up brings you to a more efficient range of RPMs.

Rpm of a car decrease when we shift the gear to a higher position.

Methods of calculating rotation: Sensors and Techniques

Although a variety of technologies can be used to measure rotation, the two most commonly employed are optical and magnetic. The basic optical methods rely on either reflection or interruption.

Tachometers:

The tachometer is a device designed to measure rotational or surface speed either in contact or non-contact way. Tachometers are widely used to measure the rotational speed of motors, conveyor belts, and other moving or rotating systems. RPM measurement with a tachometer can simply be divided into three popular methods

Mechanical:

This is still commonly used for low resolutions between 20 and 20,000 rpm.

Optical:

Here rotation is transmitted to the measuring instrument via an infrared (IR) light beam/laser beam coming from the instrument, which is then reflected by a reflective tape on the object.

Stroboscopic:

It has clear advantages over other measuring methods using mechanical or optical sensors. It can measure the RPM of even very small objects.

RPM measurement techniques

RPM, defined as revolutions per minute, is an internationally accepted expression of rotational velocity. It refers to the number of revolutions a rotating object makes on its own axis in one minute.

By Direct Observation:

- Pick a place on the rotating object to observe.

- Get a timer

- Start the timer.

- Start counting the number of rotations your marked arm or blade makes

- Stop counting when 1 minute has elapsed

Frequency measurement and period measurement are two widely accepted methods for determining RPM. Frequency measurement is better for fast-moving devices such as motors and turbines, while the period measurement is better for devices that move more slowly, such as shafts.

When using frequency measurement as a method of monitoring RPM, the key factor is the number of pulses being sensed per revolution (PPR). This method works well with high-PPR sensors and works poorly for low-PPR sensors.

When using the frequency measurement method, you can calculate the RPM using this equation:

RPM = (Pulse Frequency in pulses/sec)×(60 sec/min)/(Sensor pulses/revolution) = Revolutions/Minute

This equation shows the relationship between frequency and period as Frequency = 1/Period

When using period measurement to monitor RPM, the RPM can be calculated by using the equation:

RPM = 60/Pulse period x PPR

Also read: What is sound? To understand this better.

In addition, note that the frequency method is good for zero-speed detection. If you use frequency method to monitor the RPM, you can know the shaft has stopped when the frequency being sensed drops to zero. On the other hand, if you use the period method, the main issue is determining how much time to allow between pulses before deciding that the shaft has stopped. Basically, this method requires a little more complex logic!

RPM of various machines:

Washing machine: 1000 to 1400 range (Max)

Ceiling fan-56 Cm (Max)-RPM =218 for 3/16 thick blades, and 164 for 1/8 thick blades. Car engines usually reach up to 7000 RPM and motorcycle engines up to 10,000 RPM.

Car engines usually reach up to 7000 RPM and motorcycle engines up to 10,000 RPM. RPM of typical airline’s turbofan engines are around 8,000 to 10,000 rpm.

RPM of typical airline’s turbofan engines are around 8,000 to 10,000 rpm.

- Stepper motor turns 20 rotations per second (1200 RPM)

For more info on RPM and Measurements visit www.svibtech.net,

Follow us and stay connected to know more about Condition Monitoring and measurements.

“The Key to Productivity is Rotate your avoidance techniques”